How To Repair A Washer Machine

DIY Washing Auto Repair

Updated: Feb. 28, 2022

No feel necessary for these easy washing auto repair fixes

Washing motorcar repair: Prepare 90 percent of clothes washer breakdowns with these four easy fixes, including filling and draining issues, grinding noises and a failure to spin. Y'all'll avoid the $80 - $150 service call.

Yous might besides like: TBD

- Time

- Complexity

- Price

- A full day

- Beginner

- $51–100

Overview: Time, tools and savings of washer repair

Instead of searching the cyberspace for "washer repair almost me", we'll show yous how to prepare it yourself. Washing machine repair may sound complicated, but these machines are pretty simple inside. With a few bones tools and the steps nosotros evidence here, you can solve most problems yourself—and save the cost of a service call ($80 to $150). Nosotros won't comprehend every gear up, merely the repairs we prove will correct about 90 percent of washer troubles, like Maytag washer repair or Kenmore washer repair.

These common washer repairs are a snap for the boilerplate do-information technology-yourselfer. You'll need a socket set or nut drivers, screwdrivers and a flashlight. Repairs can take as little as an 60 minutes, just set bated a full morning time to diagnose the trouble, get parts and complete the repair. To find parts, check the xanthous pages under "Appliance Parts" or search online for "appliance parts" for Maytag washer troubleshooting or a washer repairman.

Figures A and B on the following pages show two common washer styles. The outer chiffonier shown in Figure A (Whirlpool and some other brands) lifts off completely, giving you access to all the parts. The washer shown in Effigy B (Maytag and another brands) has removable front and back panels.

Tip: Make certain your washer has power! Unplugged cords and tripped breakers are common causes of apparatus "breakdowns."

For more coin-saving fixes, blazon "appliance repair" in the search box above.

Figure A: Whirlpool-Type Washer

To remove the outer cabinet from this type of washer, first pull off the side trim pieces and remove the retaining screws. Flip the console up and release the spring clips with a screwdriver. Tilt the cabinet forward and elevator the cabinet off.

Annotation: Figure A showing Whirlpool washer repair is available in pdf format in Boosted Information below.

Figure B: Maytag Washer Repair

To remove the front panel on this blazon of washer, yank the lesser of the panel outward (you may have to first remove screws). Pull the panel down and out.

Note: Figure B of a Maytag washer repair is available in pdf format in Additional Information beneath.

Caution

Unplug your washer before yous brainstorm any testing or repairs.

Set 1: Grinding dissonance

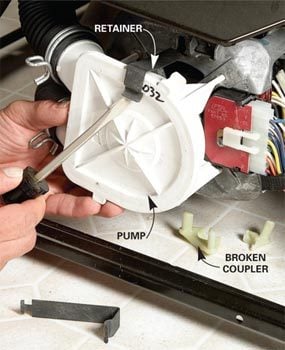

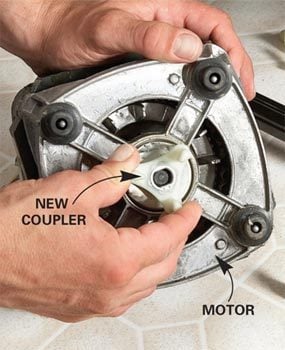

If you lot own a Whirlpool direct-drive washer (the water hoses attach to the left side when viewed from the back), y'all've probably got a cleaved coupler—a common failure acquired by overloading the car. Information technology's an easy and cheap fix, about $22.

Fix 2: Draining problems

When article of clothing or jewelry gets stuck in the hose to the pump or in the pump itself, the auto won't drain and you might hear squealing or grinding or aroma burning rubber. First remove the hose that goes from the tub to the pump (drain the h2o into a bowl) and check for stuck socks (yeah, that's where they go). So run a coat hanger through the tube and pull out the stuck objects. Adjacent check the pump for cleaved blades past shaking it. Rotate the pump shaft to make sure it spins freely. Replace the pump if yous notice any harm ($55 for Maytag; $44 for Whirlpool). If you see any burned or melted sections on the belts, supercede them ($35 a set). Maytag belts are especially designed, so don't substitute an ordinary "Five" belt.

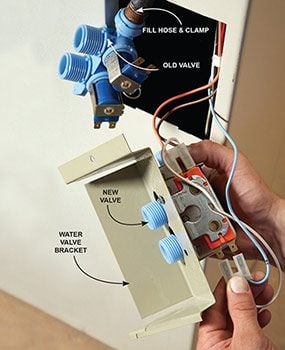

Ready three: Tedious fill or no fill

If your washing machine fills slowly or won't fill at all, attempt cleaning the inlet screens on the h2o valve. To see how, blazon "inlet screen" in the search box above. If that doesn't assist, supercede the unabridged water valve assembly ($35).

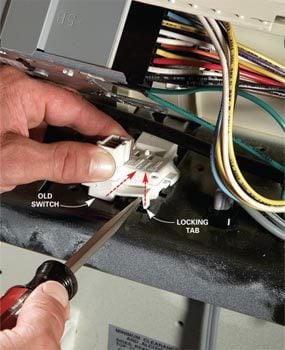

Set 4: Won't agitate or spin

If the machine fills with water and so but sits there, doubtable a broken lid switch. To test the switch, you'll need a continuity tester (about $8) or a multimeter (nearly $xv). If you don't know how to apply a multimeter, type "multimeter" in the search box to a higher place. Remove the wires connected to the switch and touch the tester'south probes to the switch's connectors. As you open and close the chapeau, readings should alternate between continuity and no continuity. If not, replace the switch ($33).

To replace the switch on a Whirlpool-type washer (Effigy A), just remove the ii screws and screw in the new one. To get at the switch on a Maytag-blazon washer (Figure B), you'll take to unscrew the admission console backside the console and replace the switch as shown here. Recollect to raise the lid earlier you remove the old switch.

Tip: Never drop a washing machine's lid! Slamming the chapeau eventually wrecks the lid switch.

Boosted Data for Washing Auto Repair

- Figure A: Whirlpool-Blazon Washer

- Figure B: Maytag-Blazon Washer

Required Tools for this Washing Machine Repair Projection

Have the necessary tools for this DIY washing automobile repair project lined upward before you kickoff—you'll relieve time and frustration.

You also might need a multimeter or continuity tester.

Required Materials for this Washing Machine Repair Project

Avoid terminal-minute shopping trips by having all your materials ready ahead of time. Here's a list.

Originally Published: November 28, 2022

How To Repair A Washer Machine,

Source: https://www.familyhandyman.com/project/diy-washer-repair/

Posted by: tatethicale.blogspot.com

0 Response to "How To Repair A Washer Machine"

Post a Comment